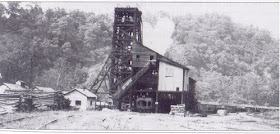

Coke ovens at Poland Mines 2009 courtesy Of SWPA Rural Exploration

In the Ten Mile Creek area, Marianna, the Champion Mine at Besco, Dilworth at Rices Landing and Poland Mines # 2 all had coke ovens operating at one time or another. At most mines, a coking operation was set up as an adjunct to the mine, most mines producing more coal than they could process to coke. At Besco, with 257 ovens, the entire output was made to coke and shipped out that way. All coke ovens on this side of the river were of the beehive type as were the majority in western Pennsylvania. The later rectangular ovens were invented by W.J. Rainey engineers starting around 1905 and were adopted at a dozen larger works in the Connellsville and Klondike regions. This type was more mechanized and required higher labor skills. The final answer was using by-product ovens that captured all the gasses for use and brought the coking process to it's ultimate efficiency. This kind of operation was done best, not on site, but in large, dedicated works like the Clairton Coke Works, opened in 1918 and still the largest in the world. In the 1970's and 80's, the company I worked for, Ohio Barge Line, had at least 5 big boats moving coal from Kentucky to feed the ovens at Clairton, each boat bringing over 22,000 tons a week. There were dozens of other boats, all towing coal to there from out of the Mon, Allegheny and Ohio river mines.

The later rectangular ovens were invented by W.J. Rainey engineers starting around 1905 and were adopted at a dozen larger works in the Connellsville and Klondike regions. This type was more mechanized and required higher labor skills. The final answer was using by-product ovens that captured all the gasses for use and brought the coking process to it's ultimate efficiency. This kind of operation was done best, not on site, but in large, dedicated works like the Clairton Coke Works, opened in 1918 and still the largest in the world. In the 1970's and 80's, the company I worked for, Ohio Barge Line, had at least 5 big boats moving coal from Kentucky to feed the ovens at Clairton, each boat bringing over 22,000 tons a week. There were dozens of other boats, all towing coal to there from out of the Mon, Allegheny and Ohio river mines.

By-product ovens outpaced beehive ovens by 1919 and eventually replaced the beehive ovens in the region by 1925, although some continued to operate as late as 1960.

Many older folks remember the way the nighttime sky would be lit up from the rows of ovens. I remember, as a child, seeing the glowing ovens of Alicia reflected on the river above Brownsville as we drove up the river road.

In the Ten Mile Creek area, Marianna, the Champion Mine at Besco, Dilworth at Rices Landing and Poland Mines # 2 all had coke ovens operating at one time or another. At most mines, a coking operation was set up as an adjunct to the mine, most mines producing more coal than they could process to coke. At Besco, with 257 ovens, the entire output was made to coke and shipped out that way. All coke ovens on this side of the river were of the beehive type as were the majority in western Pennsylvania.

The later rectangular ovens were invented by W.J. Rainey engineers starting around 1905 and were adopted at a dozen larger works in the Connellsville and Klondike regions. This type was more mechanized and required higher labor skills. The final answer was using by-product ovens that captured all the gasses for use and brought the coking process to it's ultimate efficiency. This kind of operation was done best, not on site, but in large, dedicated works like the Clairton Coke Works, opened in 1918 and still the largest in the world. In the 1970's and 80's, the company I worked for, Ohio Barge Line, had at least 5 big boats moving coal from Kentucky to feed the ovens at Clairton, each boat bringing over 22,000 tons a week. There were dozens of other boats, all towing coal to there from out of the Mon, Allegheny and Ohio river mines.

The later rectangular ovens were invented by W.J. Rainey engineers starting around 1905 and were adopted at a dozen larger works in the Connellsville and Klondike regions. This type was more mechanized and required higher labor skills. The final answer was using by-product ovens that captured all the gasses for use and brought the coking process to it's ultimate efficiency. This kind of operation was done best, not on site, but in large, dedicated works like the Clairton Coke Works, opened in 1918 and still the largest in the world. In the 1970's and 80's, the company I worked for, Ohio Barge Line, had at least 5 big boats moving coal from Kentucky to feed the ovens at Clairton, each boat bringing over 22,000 tons a week. There were dozens of other boats, all towing coal to there from out of the Mon, Allegheny and Ohio river mines. By-product ovens outpaced beehive ovens by 1919 and eventually replaced the beehive ovens in the region by 1925, although some continued to operate as late as 1960.

Many older folks remember the way the nighttime sky would be lit up from the rows of ovens. I remember, as a child, seeing the glowing ovens of Alicia reflected on the river above Brownsville as we drove up the river road.

In the early decades of the last century as the new mines opened in Washington and Greene counties there was what I choose to call an exodus of sorts from the Fayette county mines. Many folks in the Ten Mile area can trace family roots back to Fayette county patch towns. Modern patch towns with indoor plumbing, electric lights, porches, general improvements to roads and grounds must have been part of the attraction as well as the idea of starting out a new life in a new place. Mather , Crucible, Richeyville and Marianna with their movie houses, ice cream parlors, ball fields and playgrounds, all built by the company, looked pretty good to these, many of them first generation Americans, coming from the old worn out patch towns to the east. Marianna's and Clarksville's ( Williamstown ) brick homes even had basements, unheard of in most older patches. Also, some of the older mines were being played out after many years of mining. Modern technology was already beginning to displace workers, more mechanized mining and coking meant the loss of many jobs. A lot of young men, miners already themselves, took the opportunity to strike out from the old family home to start a new life on their own in a new patch.

In the early decades of the last century as the new mines opened in Washington and Greene counties there was what I choose to call an exodus of sorts from the Fayette county mines. Many folks in the Ten Mile area can trace family roots back to Fayette county patch towns. Modern patch towns with indoor plumbing, electric lights, porches, general improvements to roads and grounds must have been part of the attraction as well as the idea of starting out a new life in a new place. Mather , Crucible, Richeyville and Marianna with their movie houses, ice cream parlors, ball fields and playgrounds, all built by the company, looked pretty good to these, many of them first generation Americans, coming from the old worn out patch towns to the east. Marianna's and Clarksville's ( Williamstown ) brick homes even had basements, unheard of in most older patches. Also, some of the older mines were being played out after many years of mining. Modern technology was already beginning to displace workers, more mechanized mining and coking meant the loss of many jobs. A lot of young men, miners already themselves, took the opportunity to strike out from the old family home to start a new life on their own in a new patch.

Map Courtesy Of coalcampusa.com

My Grandfather worked in Fayette for several years at East Millsboro for Hustead-Semens and moved to Clarksville in 1924 to finish his mining career in Clyde. All three of his sons became miners, two of them for their entire lives, my father in Clarksville and my Uncle George in Richeyville. My maternal grandfather worked in a lot of different mines. Arriving from the Tatra Mountains region of Poland in 1913, he, Thomas Krencik, went to work in a Fayette county mine and the next year sent money for boat passage for his wife and daughter. He and his wife Anna had 15 more children, four of which died in infancy. Of these, seven were born in Fayette county towns like Republic, Edenburg, Lambert and Helen. Around 1924 he moved his large family to Marianna, first to a farm and later to the patch. He wasn't finished roaming, by 1937 they were living in Ontario, near Cokeburg, from which mine he retired. By that time , several of his sons who took up mining had moved to Clarksville, Ellsworth, Marianna, Cokeburg and other area towns. Many of the older people that I have interviewed have direct ties to Fayette. Years of reading obituaries have shown me that if you come from this area and your roots go back to a couple generations of miners, odds are good that at least one side of your family came from the county to the east. In this way the already decades old commercial coal and coke industry in Fayette county significantly impacted on the later growth of the Ten Mile Creek area.

The 1850 US Census of Manufactures, the earliest Census reference to coke, listed Allegheny County as the only coke producer in the United States. By the 1860 Census, four counties in the United States that produced coke were listed. It should be noted that the Clinton furnace on Pittsburgh's Southside began using coke as its only fuel in 1859. By 1870 there were estimated to be 1,300 coke ovens in the United States. All of them were beehive ovens and all were in Western Pennsylvania, 1,063 in the Connellsville region alone. Of the 2,752,475 tons of coke produced in the US in 1880, Fayette Co. produced more than 45%. Westmoreland followed with 27%, and Allegheny contributed 3.5%. Combined, the three counties yielded almost 77% of the nation's total. In 1880 seventy-two percent of the nation's beehive ovens were within the same three counties. Connellsville coke was the unequaled fuel of preference for the iron and steel industry by 1890. The peak of Connellsville coke production was in 1916, when there were more than 40,000 active ovens.

Connellsville Coke Region Maps from National Park Service

Connellsville Coke Region Maps from National Park Service